TENTS FLOOR SYSTEMS

RÖDER floor systems create a stable and strong foundation for all RÖDER tents and halls. Especially when it comes a sensitive or unstable soil where a base without anchors is used. Wear-resistant surfaces that are easy to clean, safety and economy, meet hygienic requirements and have an attractive look.

We propose an appropriate solution for any requirements, soil conditions and a corresponding system of tents and halls. The systems are flexible, modular and easy to transport. Options of ground floor systems include: Easy wood floor, a wood floor with a wood base, a wood floor with a steel base, a cassette floor, a compact floor and a floor with high loading. They can be equipped with additional coverings for a refined finish. The range varies from PVC, carpeting and laminate to wood tiles and industrial floors.

WOODEN FLOORS WITH A BASE OF WOODEN BARS

Wooden floorboards were made of shaven pine boards that are fastened together with a joggled joint. This floor structure with 2.2 cm sick boards provides stability and safety. A strip of hardwood is installed on the underside of wooden board. It increases the load capacity of the floor. Wooden boards are smooth on the sides and beveled on the end for installation in the groove of the aluminum profile. Bars from a hardwood serve not only as the basis for laying of wooden boards but also allow compensating a disfigurement of soil. The resulting groove from the base of bars can be used for laying power cables or other communications.

WOODEN FLOORS WITH A BASE OF WOODEN BARS

TECHNICAL DATA

| Standard set | • Fir panels |

| • Aluminum rail bars (profiles) | |

| • Wooden beams as a basis (option) | |

| Special equipment | • Inclined initial profile |

| Floor system material | • Anodize aluminum rail bar |

| • Impregnate fir of 2,2 cm sick with an overhang and a groove | |

| For spans | • 300 - 6000 cm |

| Plate size | • 300 x 50 cm, 500 x 50 cm |

| Floor height | • 4,5 cm |

| Load | • 500 kg/м² |

| Surface weight | • 14 kg/м² |

| Basis adjustment | • no |

| Installation | • First a tent or a hall after the floor |

| Possible use | • P-TENTS, C-TENTS, W-TENTS, H-TENTS, B-TENTS |

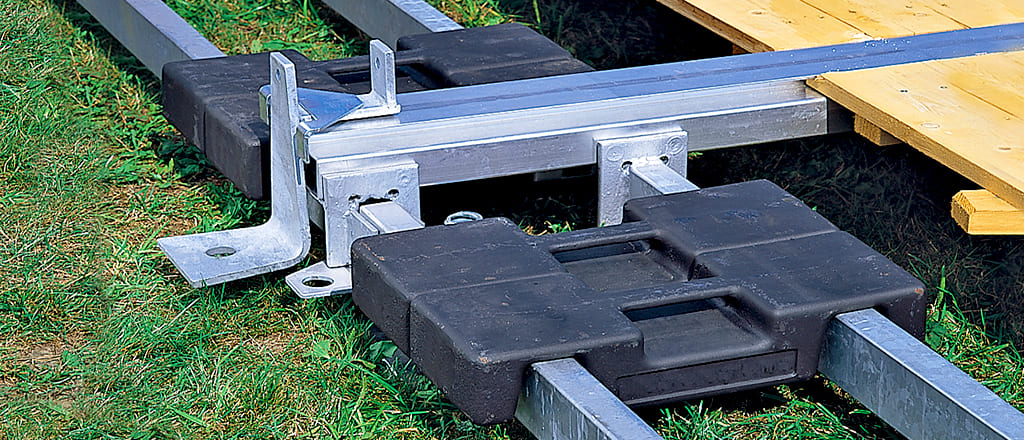

WOODEN FLOORS WITH A STEEL BASE

A base of a galvanized steel profiles can be installed quickly and easily. With the appropriate floor adapter for an appropriate RÖDER tent or hall, system a static unit is created. It can be installed without anchors with using build-in ballast loads. Wooden floorboards are made of shaven fir boards that are fastened together with a joggled join. The floor structure of boards with 2.2 cm thick provides stability and safety. A strip of hardwood is installed as a safety device, which is connected with screws. It increases a stability of the wooden floor. The plates are smoothed at the ends and are sent to the end of the board to install their aluminum profiles.

WOODEN FLOORS WITH A STEEL BASE

TECHNICAL DATA

| Standard set | • Fir panels |

| • Aluminum rail bars (profiles) | |

| • Wooden beams as a basis (option) | |

| Special equipment | • Inclined initial aluminium profile |

| Floor system material | • Anodize aluminum rail bar |

| • Impregnate fir of 2,2 cm sick with an overhang and a groove | |

| For spans | • 300 - 6000 cm |

| Shield size | • 300 x 50 cm, 500 x 50 cm |

| Load | • 350 kg/m² |

| Floor surface weight | • 23 kg/m² |

| Base adjustment | • yes |

| Installation | • First a tent or a hall after the floor |

| Possible use | • P-TENTS, C-TENTS, W-TENTS, H-TENTS, B-TENTS |

CASSETTE FLOOR

The cassette floor is a high quality and visually attractive system. Aluminum cassettes are connected to the intermediate profile at the joint and due to their stability, an additional base is not necessary. The cassette floor can be easily installed manually. To increase the stability and to reduce the risk of sliding the main shields are made of plates, which were made with a stencil stamping 12 mm of wide. The shields are layered on the surface. A static unit of the cassette floor and a secondary structure are created with a suitable base adapter for RÖDER tents and halls.

WEATHER RESISTANCE AND HIGH QUALITY

TECHNICAL DATA

| Standard set | • Aluminum cassette with a non-slip plywood surface |

| • Aluminum rails | |

| • Aluminum frame | |

| • Floor height adjustment adapter | |

| Special equipment | • Aluminum cassette with plywood surface and aluminum plate |

| Remark | • Non-slip surface, easy to clean, for kitchen, public companies and medical premises |

| Floor system material | • Anodized aluminum, Frame made of anodized aluminum |

| • Plywood 1,2 cm, non-slip, integrated into aluminum frame | |

| For spans | • 300 - 6000 cm |

| Plate size | • 200 x 100 см, 250 х 125 cm, 300 х 100 см, 500 х 100 cm |

| Floor height | • 6 cm |

| Load | • 350 kg/m² |

| Floor surface weight | • 18 kg/m² |

| Basis adjustment | • yes |

| Installation | • First the cassette floor after a tent or a hall |

| Possible use | • P-TENTS, C-TENTS, W-TENTS, H-TENTS |

COMPACT FLOOR

The patented and certified compact floor can be used for all tent and hall systems with a module size 300 or 500 cm. The 2.2 cm thick floor panels are directly screwed to the frame profile and installed easy and quickly. The compact floor can be installed without fastening for structures with the spans up to 2000 cm. An additional ballast is necessary for the floor for the premises with a width of 1500 cm. A statistic unit of compact floor and a structure is created for a tent with an appropriate adjustment of the floor base.

EASY INSTALLATION

TECHNICAL DATA

| Standard set | • Aluminum cassette with a non-slip surface |

| • Aluminum frame | |

| • Aluminum base beams | |

| • Floor height adjustment adapter | |

| Special equipment | • Ballast loads for spans over 2000 cm |

| Remark | • For all tent systems with a module 300 or 500 cm |

| Floor system material | • Galvanized steel profiles |

| • Wooden panels glued 2,2 cm thick | |

| • Height adjustment adapter made of galvanized steel | |

| For spans | • 300 - 6000 cm |

| Plate size | • 250 x 100 cm, 200 х 100 cm, 150 х 100 cm |

| Floor height | • 6 cm |

| Load | • 500 kg/m² |

| Floor surface weight | • 30 kg/m² |

| Base adjustment | • yes |

| Installation | • First the floor after a tent or a hall |

| Possible use | • P-TENTS, C-TENTS, W-TENTS, H-TENTS, B-TENTS |

Floor for heavy loads

Floor for heavy loads can be installed only with mechanisms (it is impossible to install this floor manually). Standard forklifts for installation and transportation are used for installation each floor panel. Separate floor panels are connected by means of lining connecting plates. An additional base is necessary every 250 cm to avoid vibration and provide high pressure loads. Due to high stability this floor can easily work with heavy equipment with weight up to 3.5 tons. It gives a lot of advantages for use at events, in industry and at exhibition space. The static unit is created by means of the appropriate height adjustment adapter for the correspondent tent or hall.

FOR REMINDING AND BIG PROJECTS

TECHNICAL DATA

| Standard set | • Steel frames with adjustable base plate |

| Special equipment | • Ballast loads for spans over 2000 cm |

| • Floor height adjustment adapter | |

| Remark | • Installed by means of machines (for example forklift) |

| Floor system material | • Galvanized steel profiles |

| • Wooden plates 2,2 cm are installed in a steel frame | |

| • Height adjustment adapter made of galvanized steel | |

| For spans | • 1000 - 6000 cm |

| Plate size | • 500 x 250 cm, 1000 х 250 cm |

| Floor height | • 10 cm |

| Load | • 500 kg/m² |

| Floor surface weight | • 50 kg/m² |

| Basis adjustment | • yes |

| Installation | • First the floor after a tent or a hall |

| Possible use | • P-TENTS, C-TENTS, W-TENTS, H-TENTS, B-TENTS |